Description

IAG 750 EJ25 2.5L SUBARU SHORT BLOCK

THE PROBLEM SOLVER

The IAG 750 Short Block is designed to solve the majority of common problems which plague modified EJ25 engines, especially at higher horsepower levels. The IAG 750 short block builds off our IAG 550 block’s strengths by adding our proprietary closed deck system. This system strengthens and supports the cylinder walls to prevent cracks which can occur with increased cylinder pressures. (This is the most common issue when increasing horsepower.) The IAG 750 also features 99.75mm JE Forged Pistons and IAG Spec H beam connecting rods, along with ACL or King Race bearings. These components also significantly strengthen the common failure points such as cracked ring lands and spun bearings.

BUILT WITH 100% NEW COMPONENTS

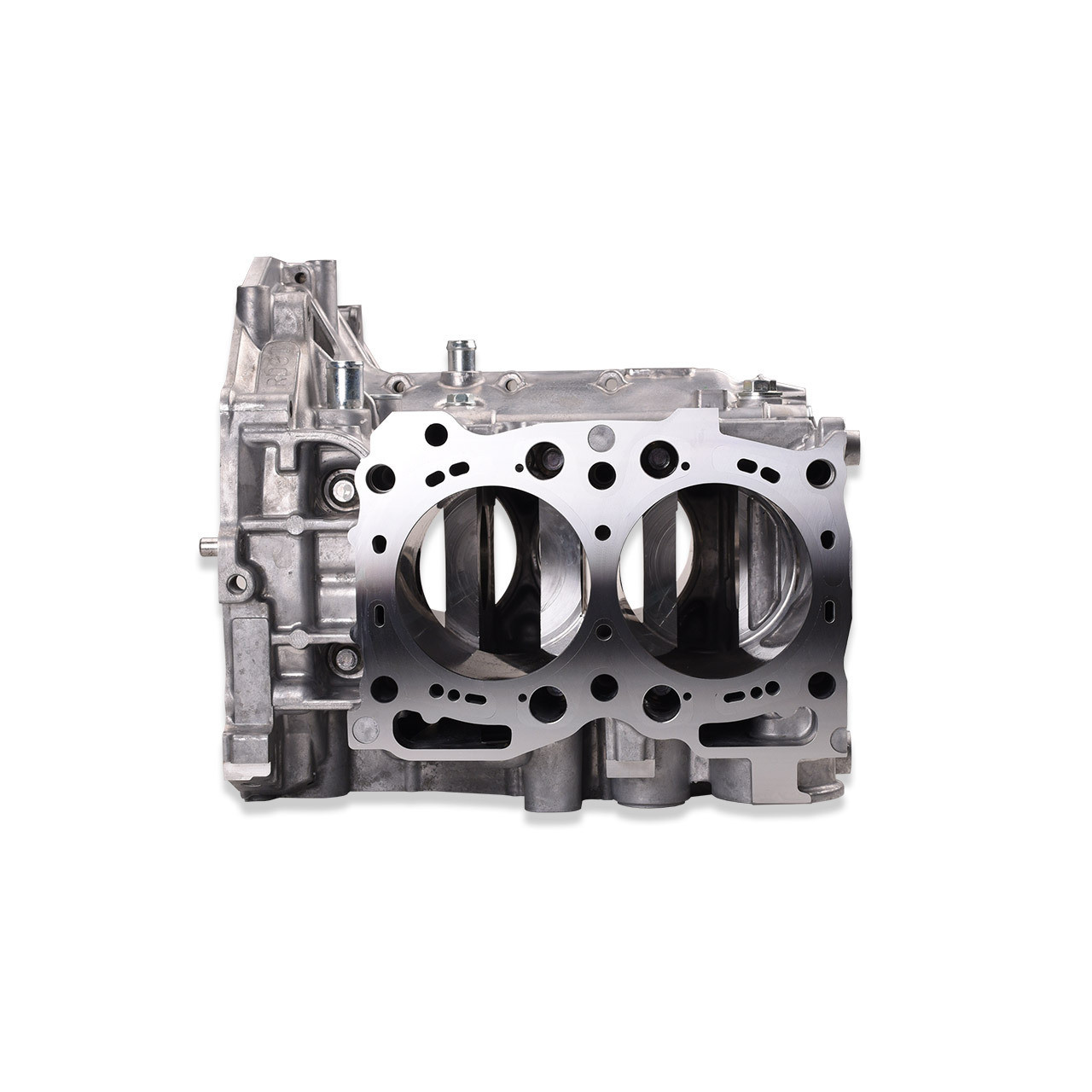

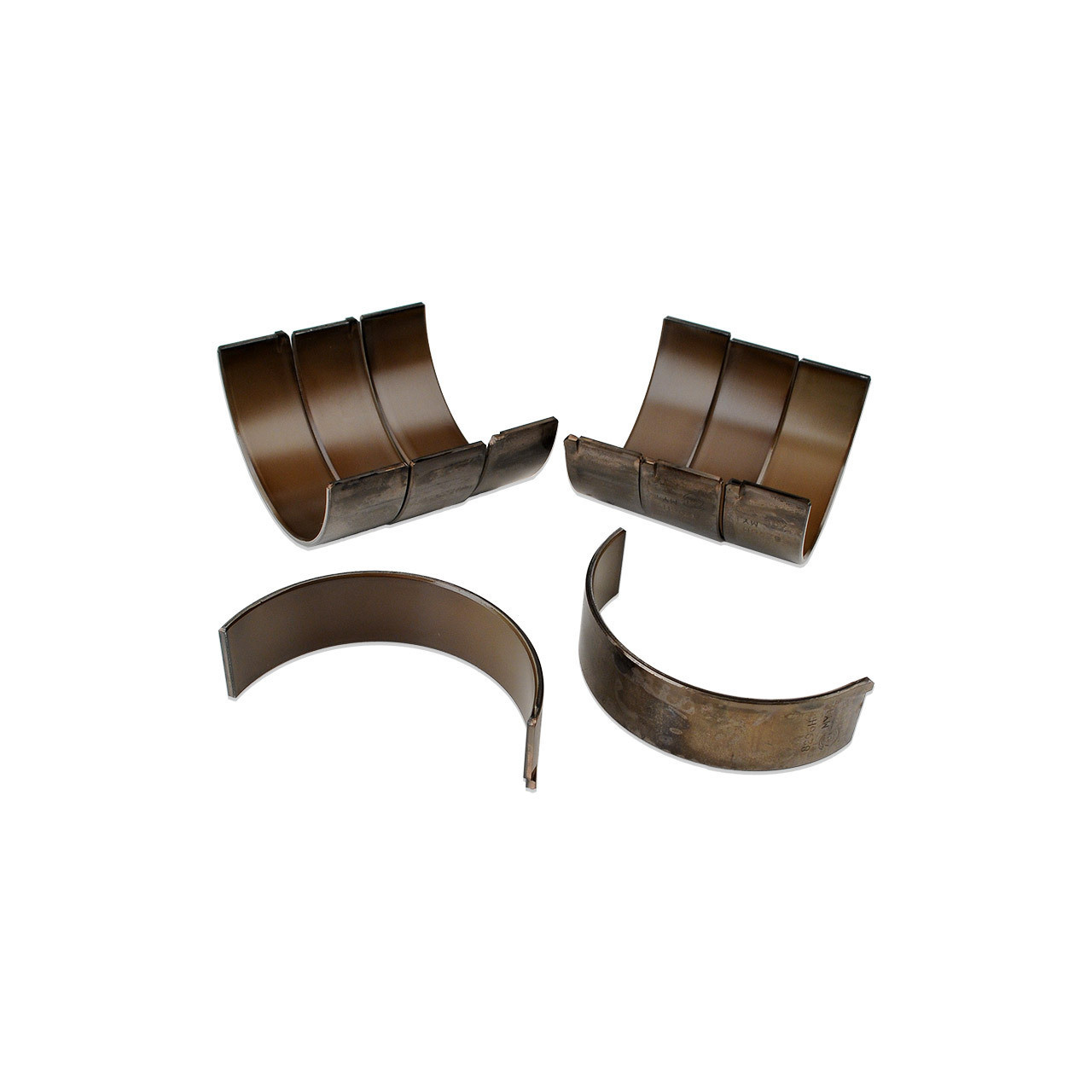

The IAG 750 Short Block starts with brand new Subaru 2.5L engine case halves. Our machinists machine the assembled case halves in our Haas VF-4SS CNC mill to accept the IAG Closed Deck inserts, transforming the block into a solid deck. Next, a deck pair of deck plates are attached and the short block is bored and honed to 99.75mm in our in-house Sunnen SV-30 computer controlled cylinder hone. IAG’s in-house honing process allows us to set custom piston to wall clearances to ensure quiet operation and reduced oil consumption. The modified case halves are then assembled using a new 2017+ Subaru 2.5L nitride treated STI crankshaft and IAG-Spec Tuff H-Beam connecting rods with ARP rod bolts. IAG Short blocks feature ACL or King Race rod and main bearings and are all balanced and blueprinted. Finally, the case halves are sealed with new OEM main/case bolts and sealant.

CLOSED DECK FOR EXTRA STRENGTH

Our unique closed deck system significantly increases the strength of the OEM case halves. This process supports the cylinder walls at the top of the case in order to prevent flexing and possible cracking where the case bolt reliefs are cut into the back of the cylinder wall.

During the installation process we machine the assembled case halves in our Haas VF-4SS CNC mill to accept the IAG Closed Deck inserts. Once the case has been machined we heat it in an oven while freezing the specially machined inserts with liquid nitrogen. The inserts are then pressed into place and then machined to a mirror finish.

The unique inserts feature small passages that allow needed coolant flow to the deck surface. This means that the closed deck system does not affect the block’s cooling ability and will not cause overheating, even in daily drivers.

FORGED PISTONS, DESIGNED FOR BOOST

Each IAG 750 Short Block features IAG Spec JE FSR 99.75mm Forged Pistons. These 2618 T6 Alloy high-strength pistons have been specifically designed to support increased cylinder pressures which come with more boost. FSR forgings reduce mass and wear caused by friction without sacrificing strength. This is accomplished by using an asymmetrical skirt design instead of the traditional full-round skirt, also this reduces weight significantly. Featuring smooth flowing radii on the domes and dishes, the design promotes excellent flame travel. The pistons are secured to the rods with .905 x 2.250″ x .210″ wall 9310 steel wrist pins with Tru Arc locks. The thicker steel wrist pins support additional power over the standard .180″ pins.

IAG 750 Closed Deck Includes:

- Case Halves –Converted to Closed Deck using brand new Subaru OEM case halves, bored and honed to 99.75mm.

- Pistons –IAG-Spec JE FSR 99.75mm 2618 Forged Pistons, Ring Set, .210″ 9310 Steel Wrist Pins, Clips, (Perfect Skirt Coating and Offset Wrist Pins)

- Connecting Rods –IAG-Spec Tuff H-Beam / ARP2000 Rod Bolts.

- Rod / Main Bearings –ACL or King Race bearings.

- Crankshaft –Standard New Subaru Nitride Treated 2017+ STI Crankshaft.

- Case / Main Bolts –Standard FHI Subaru case bolts.

Compression Ratio:

- 8.5:1 on D Cylinder Heads (EJ255)

- 8.2:1 on B, V and W EJ257 Heads with standard thickness gasket.

- 9.5:1 on S20 Heads

Power: The IAG 750 Short Block has a power output rating of 750 BHP